Feedback from consumers TD "FLATTER"

TD «Flatter» is deservedly recommended for use in various fields of activity. On this page, we have tried to collect recommendations from our consumers from different industries.

Mechanical engineering

Mechanical engineeringTver, Russian Federation

Bor, Russian Federation

- Replacing white spirit as a degreaser with «Flatter» tter detergent is expedient from the point of view of improving the quality of surface preparation of parts before painting. Increasing the protection of workers during degreasing operations. Reducing the cost of carrying out the operations of annealing parts before painting.

Transportation

TransportationMoscow, Russian Federation

Cheboksary, Russian Federation

Moscow, Russian Federation - depot Krasnaya Presnya - Ministry of Internal Affairs

- Having carefully studied the presented materials for the «Flatter» concentrated industrial paste detergent, the State Fire Supervision Department considers it possible to use this material as a fireproof detergent in the technological processes of washing and degreasing rolling stock, escalator equipment, etc.

- The use of this tool will make it possible to remove kerosene or other combustible liquids currently used in the subway from the technological process of washing and degreasing and reduce the fire load.

Moscow, Russian Federation - depot Krasnaya Presnya

Moscow, Russian Federation - depot Sokol

- The felt-tip pen, stickers, adhesive film, grease mixed with dirt (except paint) are removed satisfactorily from the indicated surfaces.

- The washing process is carried out manually, does not require special mechanisms, personal protective equipment and takes little time.

- The solution during washing does not cause irritation of the skin and mucous membranes of the eyes.

Moscow, Russian Federation - depot Nakhabino

Moscow, Russian Federation - depot Orekhovo-Zuevo

- Washing was carried out with a 5% solution of the agent in a washing machine for trolley parts.

- During washing, it was revealed that oil-lubricating impurities were completely removed, mud deposits were partially removed, rust and paintwork residues were not removed.

- When washing with a 3% «FLATTER» solution using a rag, oil and mud contamination on horizontal working surfaces was completely removed.

- When washing with a 3% solution of «FLATTER» using a rag, the walls of the passenger car body were completely removed, the paintwork was not damaged.

Moscow, Russian Federation - depot Ramenskoye

- The quality of washing the rolling stock with the «Flatter» detergent solution is quite high and meets the current standards.

- Detergent well degreases the washed surfaces.

- The solution, removing smudges, rust and dirt, does not damage the paintwork, the gloss of the paintwork is preserved, there is no chalking.

- Means poorly foams, is well dissolved in water, has no unpleasant smell.

Saratov, Russian Federation - depot station «Neftyanaya»

- We have tested the concentrated detergent «Flatter» in a washing machine for washing brake devices.

- The detergent concentration in the machine was 1.5%. At this concentration, the quality of washing of brake devices is satisfactory. The amount of detergent in the machine was used less than recommended on the «Flatter» packaging.

Moscow, Russian Federation

Due to the absence of a jet washer in shop No. 3, the bearings were washed manually.

- Working solution concentration - 2%

- Solution temperature 30-40º С

- The solution container was loaded with bearings 30-32413, 30-32310, 80-32419, 80-92320, 20-32322.

- The bearings were generously lubricated with LRW grease.

- The exposure time of the parts in the solution is 5 min.

- After soaking in the solution, the parts were wiped with a rag.

The solution left from washing the bearings was used to wash the floor area of the production room of shop No. 3.

Conclusion:

- The quality of washing bearings from abundantly applied grease with a 2% solution of «Flatter» paste is high. The grease is completely removed from the surface of the products.

- The floor of the production area was washed from dirt and grease.

Kanash, Russian Federation

Due to the fact that the washing machine was in operating mode, the bearings were washed in manual mode:

- Working solution concentration - 2%

- Solution temperature - 40-50° С

- Bearings after disassembling the axlebox assembly (richly lubricated with grease) were immersed in a container with a solution and kept in the solution for 5 min.

- After soaking in the solution, the parts were wiped with a rag.

The solution left after washing the bearings was used to wash the area of the floor of the roller section of the undercarriage shop.

Conclusion:

- The quality of cleaning the bearings with a 2% solution of the «Flatter» paste is good, the grease is completely removed from the surface of the parts.

- The floor of the production area was washed from dirt and grease.

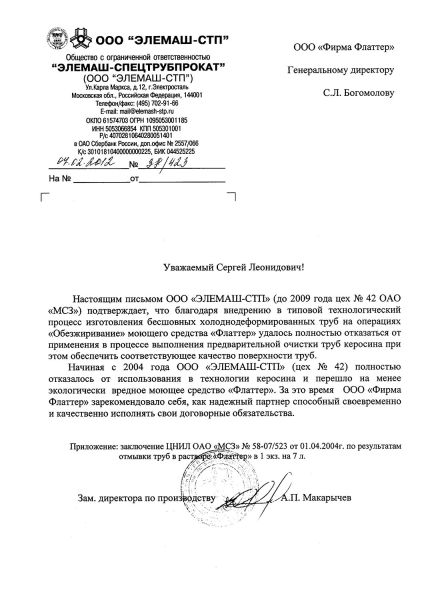

Metal processing

Metal processingElektrostal, Russian Federation

- A comparison of the amount of residual contamination on the pipes after washing showed that the quality of cleaning in «Flatter» is no worse than in kerosene.

- When processing pipes in an aqueous solution of «Flatter», the main part of the lubricants, together with the sludge, is released in the form of sludge. This facilitates the separation of contaminants and increases the working time of the solution.

- Neutralization of the aqueous part of the «Flatter» waste solutions using the standard CSO technology showed that the COD values decreased by 5-10 times (from 9.6 - 11.8 g/l to 1.06 - 2.1 g/l.), and the content of petroleum products in clarified solutions - several times (from 0.070 - 0.200 g/l to 0.028 - 0.029 g/l).

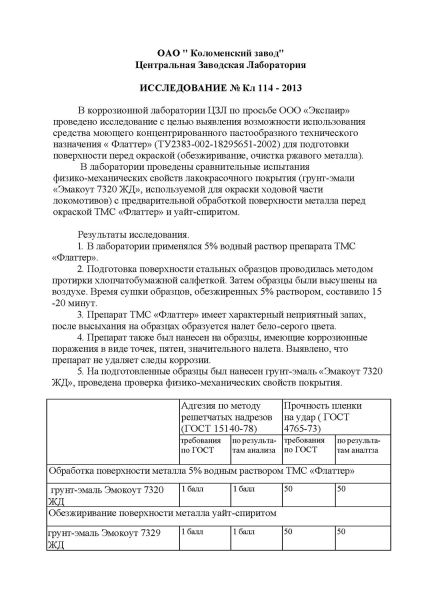

Kolomna, Russian Federation

- The physical and mechanical properties of the paintwork, the treatment for which was carried out with the TD «Flatter» preparation, have the same indicators compared to the samples treated with white spirit according to the standard technology.

- Considering the obtained data, CPL can recommend TD «Flatter» for degreasing surfaces to be painted.

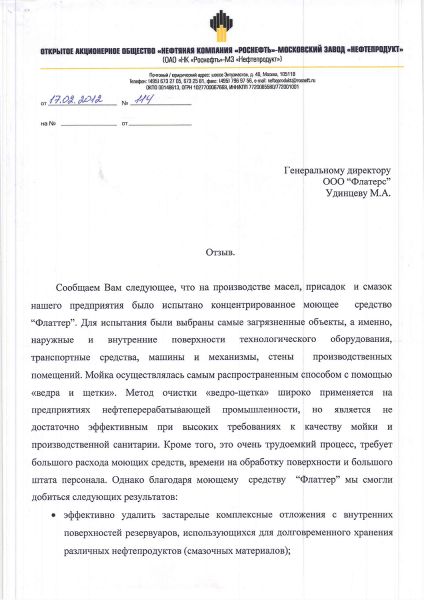

Oil and gas industry

Oil and gas industryMoscow, Russian Federation

The «bucket-brush» cleaning method is widely used in the oil refining industry, but is not effective enough with high requirements for the quality of washing and industrial sanitation. In addition, this is a very labor-intensive process, requiring a large consumption of detergents, time for surface treatment and a large staff. However, thanks to the Flutter detergent, we were able to achieve the following results:

- effectively remove old complex deposits from the inner surfaces of tanks used for long-term storage of various petroleum products (lubricants);

- clean the oily concrete floor, which was not previously possible with more than one detergent;

- at the site for the production of special lubricants, it was possible to clean the metal containers used for the preparation of soot lubricants;

- save detergent by 3-5 times compared to traditional detergents («nefras», kerosene);

- reduce labor costs and reduce surface treatment time.

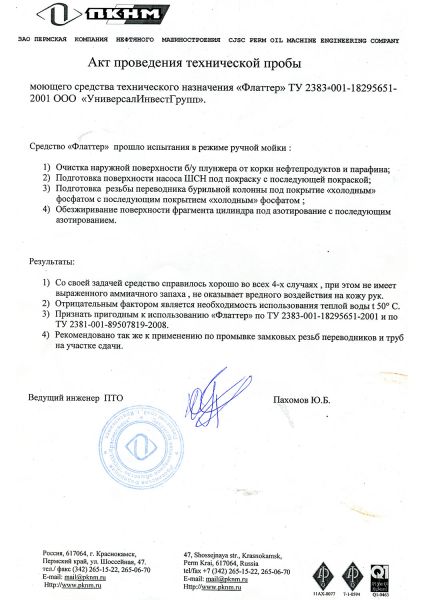

Perm, Russian Federation

«Flatter» has been tested in manual washing mode:

- Cleaning the outer surface of the used plunger from the crust of oil products and paraffin;

- Preparation of the surface of the slurry-suspension pump for painting with subsequent painting;

- Preparation of drill string sub threads for cold phosphate coating followed by cold phosphate coating;

- Degreasing the surface of a cylinder fragment for nitriding, followed by nitriding.

Results:

- The product coped with its task well in all 4 cases, while it does not have a pronounced ammonia smell, and does not have a harmful effect on the skin of the hands.

- A negative factor is the need to use warm water t 50° C.

- Recognize «Flatter» as suitable for use in accordance with TC 2383-001-18295651-2001 and TC 2381-001-89507819-2008.

- It is also recommended for use in flushing the interlock threads of subs and pipes at the delivery site.

Shipbuilding

ShipbuildingSeverodvinsk, Russian Federation

- Department of the chief metrologist-CPL can recommend TD «Flatter» for degreasing surfaces for electroplating and chemical cleaning of parts.

- Electroplated coatings applied on surfaces cleaned by TD «Flatter» have good adhesion to the substrate.

- TD «Flatter» can be recommended for use before oxidation, phosphating, zinc plating, nickel plating, tin plating in shop No. 6.

Utilities

UtilitiesMoscow, Russian Federation

Characteristics of the working composition: concentration - 5%, temperature 45° C.

The detergent was applied with a foam sponge. Contaminated surfaces of the form of a three-dimensional bay window, a container for storing a release agent were processed, and tests were also carried out on washing facade tiles on products of external walls.

Next, the cleaned surfaces were washed with water using a Karcher mini-sink.

As a result of work with this composition, all surfaces after treatment were washed from dirt and fat deposits, oil stains were completely removed.

Moscow, Russian Federation

According to the tests carried out at the enterprises of the dry-cleaner-laundry «Diana» in the complex technology, the highly concentrated «Flatter» paste was used as the main detergent, in the amount of 1.5 kg per 10 l of water. The consumption of this solution is 0.015 g/kg of dry laundry.

Tests were carried out on the entire range of linen (restaurant, bed, kitchen), washing overalls, jackets. During processing, very good results were obtained, i.e. high degree of whiteness.

Vehicle

VehicleMoscow, Russian Federation

- Taking into account the positive results of the work, the «Flatter» technical detergent paste is recommended for use for cleaning parts and assemblies made of various metals from fuels and lubricants, as well as for surface preparation for paint and varnish work.

- The use of «Flatter» technical detergent paste instead of kerosene, white spirit, diesel fuel and other organic solvents is advisable to reduce the fire hazard and eliminate harmful effects on humans.

Equipment repairs and maintenance

Equipment repairs and maintenanceVelikiye Luki, Russian Federation

Technical detergent «Flatter» can be recommended for cleaning parts, components and assemblies of the vehicle, equipment, containers and intra-factory transport systems, as well as internal walls and floors of industrial premises, overpasses, ramps, both manually and using high-pressure apparatus and washing machines in the conditions of JSC "VELIKOLUKSKY MEAT PROCESSING PLANT".