Feedback from consumers TD "FLATTER" - Metal processing

TD «Flatter» is deservedly recommended for use in various fields of activity. On this page you can find testimonials from our metalworking customers.

Metal processing

Metal processingElektrostal, Russian Federation

- A comparison of the amount of residual contamination on the pipes after washing showed that the quality of cleaning in «Flatter» is no worse than in kerosene.

- When processing pipes in an aqueous solution of «Flatter», the main part of the lubricants, together with the sludge, is released in the form of sludge. This facilitates the separation of contaminants and increases the working time of the solution.

- Neutralization of the aqueous part of the «Flatter» waste solutions using the standard CSO technology showed that the COD values decreased by 5-10 times (from 9.6 - 11.8 g/l to 1.06 - 2.1 g/l.), and the content of petroleum products in clarified solutions - several times (from 0.070 - 0.200 g/l to 0.028 - 0.029 g/l).

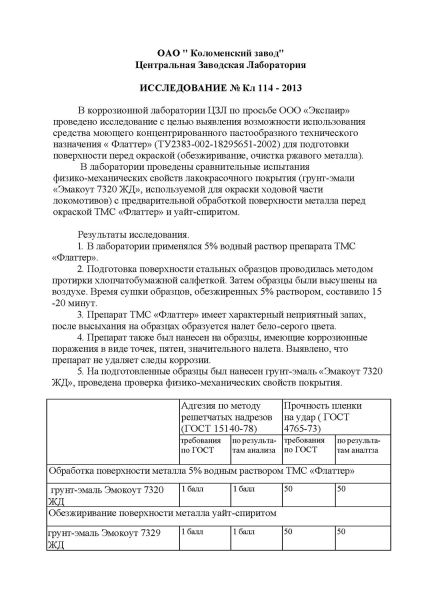

Kolomna, Russian Federation

- The physical and mechanical properties of the paintwork, the treatment for which was carried out with the TD «Flatter» preparation, have the same indicators compared to the samples treated with white spirit according to the standard technology.

- Considering the obtained data, CPL can recommend TD «Flatter» for degreasing surfaces to be painted.